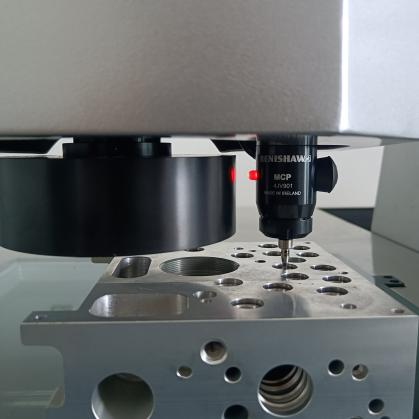

3D kov sojntsuam, tseem hu ua kev sib cuag sensor, raws li ib qho kev xaiv accessory ntawm VMM, tuaj yeem nruab nrog VMM kom ua tiav ntau hom kev ntsuas, uas muab lub kaw lus nrog kev ntsuas ntau dua thiab tsim nyog rau ntau hom kev siv.

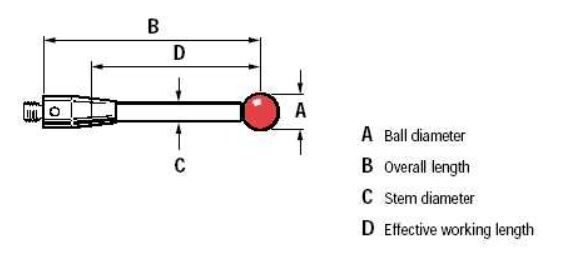

1. High precision trigger ntsuas: 3D kov sojntsuam tuaj yeem ua qhov ntsuas qhov ntsuas siab los ntawm kev ntsuas qhov sib txawv ntawm qhov sib txawv kom tau txais 3D cov ntsiab lus sib koom ua ke, yog li ua tiav qhov ntsuas qhov ntsuas siab.

2. Surface morphology ntsuas: 3D kov sojntsuam tuaj yeem tiv tauj rau qhov chaw ua haujlwm thiab tau txais cov ntaub ntawv, uas yog qhov tseem ceeb heev rau kev ntsuas qhov sib txawv ntawm qhov morphology thiab tuaj yeem muab cov ntaub ntawv geometric ntau dua.

3. Kev kuaj xyuas ib feem: VMM nruab nrog 3D kov sojntsuam tuaj yeem siv los kuaj xyuas cov yam ntxwv xws li aperture, protrusion, notch, thiab lwm yam, thiab kev ntsuas meej ntawm cov yam ntxwv no tuaj yeem ua tiav los ntawm kev ntsuas qhov ntsuas ntawm qhov ntsuas.

4. Multi-point ntsuas thiab ntsuas txoj kev npaj: 3D kov sojntsuam tuaj yeem npaj txoj hauv kev ntawm ntau lub ntsiab lus ntsuas, yog li ua tiav kev ntsuas ntau qhov ntsuas thiab txhim kho kev ntsuas kev ua tau zoo.

5. Kev txhawb nqa software thiab kev ua cov ntaub ntawv: Lub 3D kov sojntsuam yog nruab nrog kev ntsuas software, uas tuaj yeem ua haujlwm, txheeb xyuas, thiab pom cov ntaub ntawv tau, ua rau cov txiaj ntsig ntsuas tau yooj yim nkag siab thiab siv tau.

6.Kev ntsuas cov txheej txheem nyuaj: Rau qhov chaw uas muaj cov qauv tsim thiab cov duab tsis zoo, 3D kov sojntsuam tuaj yeem hloov kho thiab ntsuas tau zoo dua, yog li ua tiav cov ntaub ntawv sau ntau dua.

Daim ntawv thov

Kev teeb tsa 3D kov sojntsuam ntawm VMM yuav them rau qhov ntsuas tsis txaus ntawm lub lens optical thaum ntsib cov qauv nrog cov yam ntxwv nyuaj thiab cov qauv.Yog li ntawd, daim ntawv thov scenario overlaps nrog cov tsoos Coordinate Measuring Machine (CMM).

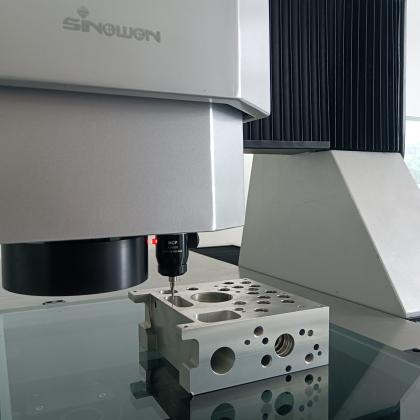

Peb pab neeg qhia tias VMM (nrog 3D kov sojntsuam) tuaj yeem xaiv thiab pom zoo hauv cov xwm txheej hauv qab no:

1. Qhov ntsuas qhov tseeb tsis tshaj lossis sib npaug ntawm (5 + L / 200) um;

2. Cov qauv uas yuav tsum tau ntsuas hauv ib hnub yog qhov loj heev, yog li kev siv CMM ib txwm siv sijhawm ntev heev;

3. Cov peev nyiaj tsis tau raws li tus nqi ntawm CMM, lossis tsis muaj chaw txaus los tso CMM.Peb tuaj yeem txiav txim siab siv VMM hloov.

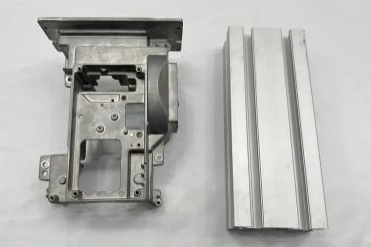

Hais txog cov khoom lag luam, thov xa mus rau:

Mechanical qhov chaw, xws li bolts, txiv ntseej, iav, ncej;

Precision mould manufacturing, xws li stamping, tuag-casting qhov chaw, optical pwm, thiab hluav taws xob ntim pwm;

Aerospace, xws li cov khoom sib xyaw ua ke ntawm cov khoom sib xyaw;

Cov khoom siv hluav taws xob, xws li qee qhov ntim khoom;

Cov cuab yeej kho mob;Xws li implants, kho mob fixtures, thiab stents.

Zoo siab txais tos koj los rau peb lub YouTube channel kom paub ntau ntxiv txog 3D touch probe ntsuas: https://www.youtube.com/watch?v=s27TOoD8HHM&list=PL1eUvesN07V9kJ5zZJUOuvUtzktCO06QK&index=4

Yog tias koj muaj qee qhov kev xav tau ntawm qhov project, thov koj xav tiv tauj peb rau kev sab laj.

Post lub sij hawm: Aug-31-2023