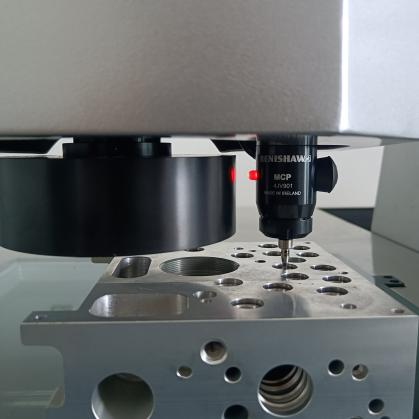

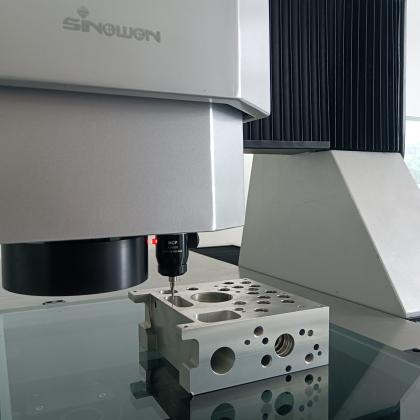

Binciken taɓawa na 3D, wanda kuma aka sani da firikwensin lamba, azaman kayan haɗi na zaɓi akan VMM, ana iya sanye shi da VMM don cimma nau'ikan ma'auni da yawa, wanda ke ba da tsarin tare da mafi kyawun ma'auni kuma ya dace da nau'ikan aikace-aikace daban-daban.

1. Babban ma'aunin faɗakarwa mai mahimmanci: Binciken taɓawa na 3D na iya yin ma'aunin faɗakarwa mai mahimmanci ta hanyar haifar da bincike akan saman daban-daban don samun maki daidaitawa na 3D, don haka samun ma'aunin ma'auni mai mahimmanci.

2. Ma'auni na ilimin halittar jiki: Binciken taɓawa na 3D zai iya tuntuɓar filin aikin kuma ya sami bayanai, wanda ke da amfani sosai don ma'aunin yanayin yanayin yanayin sararin samaniya kuma yana iya samar da ƙarin cikakkun bayanai na geometric.

3. Gano fasalin sashe: VMM sanye take da binciken taɓawa na 3D ana iya amfani da shi don gano fasalulluka kamar buɗaɗɗen buɗaɗɗen buɗaɗɗiya, haɓakawa, daraja, da sauransu, kuma ana iya samun daidaitaccen ma'aunin waɗannan fasalulluka ta hanyar ma'aunin faɗakarwa na binciken.

4. Ma'auni da yawa da tsara hanyar aunawa: Binciken taɓawa na 3D zai iya tsara hanyoyin ma'aunin ma'auni ta atomatik, ta yadda za a cimma ma'aunin ma'auni da yawa da kuma inganta ingantaccen ma'auni.

5. Tallafin software da sarrafa bayanai: Binciken taɓawa na 3D yana sanye take da ƙwararrun software na aunawa, wanda zai iya aiwatarwa, bincika, da hangen nesa da bayanan da aka samu, yana sa sakamakon ma'aunin sauƙi don fahimta da amfani.

6.Measurement na hadaddun tsarin: Ga sassa da hadaddun tsarin da kuma maras kyau siffofi, 3D touch bincike iya mafi daidaita da kuma auna, don haka samun mafi m tarin bayanai.

Aikace-aikace

Samar da binciken taɓawa na 3D akan VMM zai rama ƙarancin ikon auna ruwan tabarau lokacin fuskantar samfura tare da hadaddun fasali da tsari.Don haka, yanayin aikace-aikacen ya zo ya mamaye na'ura mai aunawa na Coordinate Measuring (CMM).

Ƙungiyarmu ta ba da shawarar cewa za a iya zaɓar VMM (tare da binciken taɓawa na 3D) kuma a ba da shawarar a cikin yanayi masu zuwa:

1. Daidaiton ma'auni bai wuce ko daidai da (5+L/200) um;

2. Samfurin da ake buƙatar aunawa a kowace rana yana da adadi mai yawa, don haka amfani da CMM na al'ada yana cin lokaci mai yawa;

3. Kasafin kudin bai dace da farashin CMM ba, ko kuma babu isasshen sarari don sanya CMM.Za mu iya yin la'akari da amfani da VMM maimakon.

Dangane da masana'antar samfur, da fatan za a koma:

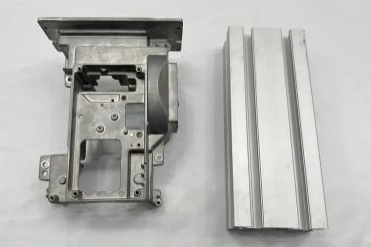

Sassan injina, irin su bolts, goro, gears, shafts;

Ƙirƙirar ƙirar ƙira, kamar tambari, sassan simintin simintin gyare-gyare, gyare-gyaren gani, da gyare-gyaren marufi na lantarki;

Aerospace, kamar kayan aikin da aka yi da kayan haɗin gwiwa;

Abubuwan lantarki, kamar wasu abubuwan da aka haɗa;

Na'urorin likitanci;Kamar su dasawa, kayan aikin likita, da stent.

Barka da zuwa tasharmu ta YouTube don ƙarin bayani kan ma'aunin bincike na 3D: https://www.youtube.com/watch?v=s27TOoD8HHM&list=PL1eUvesN07V9kJ5zZJUOuvUtzktCO06QK&index=4

Idan kuna da wasu buƙatun aikin da suka danganci, da fatan za ku iya tuntuɓar mu don shawarwari.

Lokacin aikawa: Agusta-31-2023